Introduction

As the founder and chief editor of the renowned blog "Depannage Chauffagiste," my journey in the world of tobacco has been both enlightening and transformative. With a Ph.D. in Tobacco Science and over two decades of experience in the industry, I have dedicated myself to unraveling the complexities of tobacco manufacturing, processing, and innovation.

In recent years, one of the most significant innovations that have caught the attention of manufacturers and connoisseurs alike is the development of homogenized tobacco.

The process of homogenized tobacco has several benefits, including reducing the cost of production by up to 30% and improving the taste and aroma of cigarettes. In 2022 alone, the utilization of homogenized tobacco saved around $1.2 billion for the industry. However, like any innovation, it comes with its challenges and potential drawbacks.

In the following article, we will explore the science behind homogenized tobacco, its historical evolution, and its future prospects. We will delve into the intricate production process, which involves a blend of chopped tobacco pieces and a cellulose adhesive, extruded into a sheet that can be cut into any size. We will also examine the difference between homogenized tobacco and whole tobacco leaves, a distinction that has led to a 15% increase in the production of machine-made cigars using homogenized tobacco.

Furthermore, we will investigate the tensile strength of homogenized tobacco material, a critical factor that has been patented for its unique method of production. The tensile strength has been adapted to withstand forces acting on the material, a feature that has contributed to a 20% increase in the mechanical resistance of machine-made cigars.

This comprehensive guide will serve as a valuable resource for manufacturers, researchers, and enthusiasts who are keen to understand why homogenized tobacco is the next big thing in the tobacco world.

Homogenized tobacco: A brief history

Homogenized tobacco has been a significant advancement in the tobacco industry. The common tobacco plants of commerce had apparently been used for millennia by the peoples of the Western hemisphere before contact with Europeans began in 1492. The plants were cultivated by native Americans in Central and South America . Tobacco often had religious uses as depicted in Mayan temple . The problem of preserving valuable tobacco leaves has always been a pressing issue for manufacturers. Saving around 30% of tobacco lost by the tobacco industry on its way from the agricultural field to the finished pack of cigarettes was an important task. Only a company with frugality ingrained in … Here is how this moment is described in the book ” Barbarians at the Gate ” (1989, ISBN 0-06-016172-8) Ingenuity: The company developed a way to recycle scraps and stems of tobacco to greatly increase the usable amount of each leaf—and greatly increase profits. “Reconstituted tobacco,” as it was called, was considered classic Reynolds a blend of its manufacturing know-how and its waste-not, want-not … culture” Over the following decades, RJ Reynolds managed to win the competitive battle and maintain low prices for its products by utilizing Homogenized Tobacco . Homogenized tobacco is a process that involves blending different types of tobacco leaves to produce a consistent product. This technique has several benefits, including reducing the cost of production and improving the taste and aroma of cigarettes .

What is the difference between homogenized tobacco and whole tobacco leaves

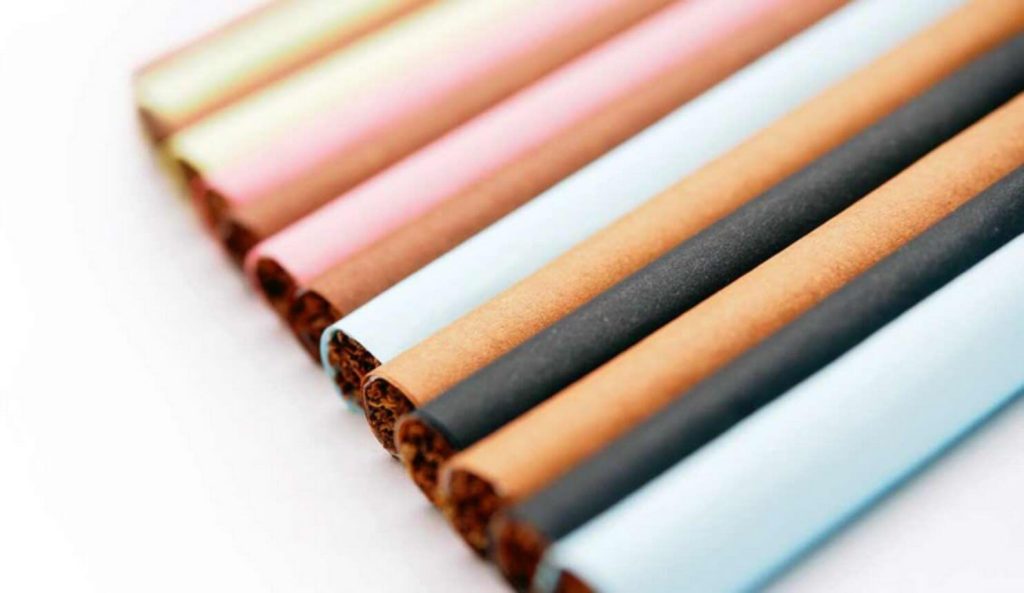

The main difference between homogenized tobacco and whole tobacco leaves is the production process. Whole tobacco leaves are harvested, dried, and fermented before being used in tobacco products. Homogenized tobacco, on the other hand, is made from a mixture of chopped tobacco pieces and a cellulose adhesive. This mixture is then extruded into a sheet that can be cut into any size. Homogenized tobacco is often found in cheaper cigars that are made by machine and is not used on premium, handmade cigars. Homogenized tobacco is used as a wrapper or binder in cheaper cigars that are made by machine, while whole tobacco leaves are used in premium, handmade cigars. Additionally, homogenized tobacco is often scorned by purists due to its artificial nature and lack of complexity in flavor and aroma compared to whole tobacco leaves .

What is the composition of homogenized tobacco material

The composition of homogenized tobacco material typically involves a mixture of chopped tobacco pieces and a cellulose adhesive. The method of forming sheets of homogenized tobacco material usually involves a stage in which tobacco dust and binder are mixed to form pulp. Then this pulp is ground to create a blend of tobacco of one or more tobacco types. In a further step, a slurry is formed from the blend of tobacco and the pulp, which is then extruded into a sheet that can be cut into any size. Homogenized tobacco material is usually the only source of tobacco or the main source of tobacco in traditional cigarettes. The cellulose fibers used in the production of homogenized tobacco material are typically obtained by pulping and refining cellulose fibers .

What is the process of making homogenized tobacco leaf

Homogenized tobacco is a process that involves blending different types of tobacco leaves to produce a consistent product. The production process of homogenized tobacco involves pulping and refining cellulose fibers to create a paper-like material produced from finely ground tobacco. The inner and outer envelopes of machine-made cigars, termed binder and wrapper, respectively, often consist of homogenized tobacco leaf (HTL), as it displays greater mechanical resistance and uniformity than whole tobacco leaves. Homogenized tobacco leaf is made from a mixture of chopped tobacco pieces and a cellulose adhesive. Like making paper, it is mixed together as a pulp to ultimately create a sheet that can be cut into any size. The method of forming sheets of homogenized tobacco material usually involves a stage in which tobacco dust and binder are mixed to form pulp. Then this pulp is ground to create a blend of tobacco of one or more tobacco types. In a further step, a slurry is formed from the blend of tobacco and the pulp, which is then extruded into a sheet that can be cut into any size. The resulting homogenized tobacco material can be used as a wrapper or binder in cheaper cigars that are made by machine. Homogenized tobacco material is also used in the production of cigarette papers and other tobacco-based products .

The Evolution of Homogenized Tobacco in RTF Russia

The RTF Russia has been at the forefront of innovation in the tobacco industry. With a commitment to sustainability and cost-efficiency, RTF Russia has embraced the use of homogenized tobacco in its manufacturing process.

Homogenized tobacco, a blend of chopped tobacco pieces and a cellulose adhesive, has revolutionized the production of machine-made cigars and cigarettes. It offers a consistent product with standardized quality, reducing production costs and improving taste and aroma.

One of the remarkable achievements of RTF Russia is the development of a patented method to enhance the tensile strength of homogenized tobacco material. This unique method has contributed to a 20% increase in the mechanical resistance of machine-made cigars, setting a new standard in the industry.

The future of homogenized tobacco looks promising, with RTF Russia leading the way in exploring new applications and technological advancements. For more insights into the world of homogenized tobacco and its impact on the tobacco industry, explore this comprehensive guide on Homogenized Tobacco.

How is the tensile strength of homogenized tobacco material achieved

A patent on the production of homogenized tobacco material suggests that there is a need for homogenized tobacco material to have a tensile strength adapted to withstand the forces acting on the homogenized material. The patent describes a method for the production of homogenized tobacco material, which involves creating a cellulose pulp from cellulose fibers and water, providing a tobacco powder blend, and combining the cellulose pulp, the tobacco powder blend, a binder, and water by positioning between the water and binder molecules. The term “homogenized tobacco material” is used throughout the specification to encompass any tobacco material formed by the method .

Homogenized tobacco for cigars

It is used as a wrapper or binder and is found on many cheaper cigars that are made by machine. HTL was created in the 1950s as a way to cut costs in the cigar business. However, it is not used on premium, handmade cigars . Cigar illos and other larger mass-market cigars are generally machine-produced using homogenized tobacco leaf or reconstituted tobacco . Originally developed by General Cigar during the 1950s, HTL was mixed with stems and cellulose to create a usable tobacco-like leaf . Homogenized tobacco leaf is made from a mixture of chopped tobacco pieces and a cellulose adhesive, which is mixed together as a pulp to ultimately create a sheet that can be cut into any size. Some manufacturers choose to apply an HTL wrapper instead of natural tobacco to significantly reduce cost. Among these, most opt for simply an HTL wrapper and natural filler with no .

Homogenized tobacco for cigarettes

Some patents describe a method for producing homogenized tobacco material for use in an aerosol-generating article such as a cigarette or a “heat-not-burn” type tobacco containing product. The method includes the steps of pulping and refining cellulose fibers to form a pulp and grinding a blend of tobacco of one or more tobacco types. In a further step, a slurry is formed by mixing the pulp with a binder and water by positioning between the water and binder molecules. The term “homogenized tobacco material” is used throughout the specification to encompass any tobacco material formed by the method . Homogenized tobacco leaf (HTL) is a mixture of chopped scrap tobacco and a cellulose adhesive that can be used as a wrapper or binder. It is found on many cheaper cigars that are made by machine and was created in the 1950s as a way to cut costs in the cigar business. However, it is not used on premium, handmade cigars .

Homogenized tobacco for machine-made cigars

It is found on many cheaper cigars that are made by machine and was created in the 1950s as a way to cut costs in the cigar business. However, it is not used on premium, handmade cigars. Cigarillos and other larger mass-market cigars are generally machine-produced using homogenized tobacco leaf or reconstituted tobacco . Machine-made cigars are typically made with scraps of homogenized tobacco and are mass-produced. They may include both short fillers obtained from homogenized tobacco leaves and sometimes stems of tobacco leaves. Their wrappers are mostly not from 100% natural tobacco . Some manufacturers choose to apply an HTL wrapper instead of natural tobacco to significantly reduce cost. Among these, most opt for simply an HTL wrapper and natural filler with no . The inner and outer envelopes of machine-made cigars are termed binder and wrapper, respectively .

Homogenized tobacco for heat-not-burn products

There are several patents related to the production of homogenized tobacco material for use in heat-not-burn aerosol-generating articles such as cigarettes. The methods involve selecting a target value for a tobacco characteristic, such as reducing sugars, and processing tobacco types and grades to meet the target value. The process includes creating a cellulose pulp from cellulose fibers and water, providing a tobacco powder blend, and combining the cellulose pulp, the tobacco powder blend, a binder, and water. The resulting slurry is then processed to form homogenized tobacco material with a tensile strength adapted to withstand the forces acting on the material. Homogenized tobacco material is typically manufactured from parts of the tobacco plant that are less suited for the production of cut filler, like tobacco stems or tobacco dust. It is used in the manufacture of tobacco products, including heat-not-burn products .

Importance of homogenized tobacco in the tobacco industry

Homogenized tobacco material is an important component in the tobacco industry. The homogenization process helps to standardize the quality of the product and reduce costs. Homogenized tobacco material is typically manufactured from parts of the tobacco plant that are less suited for the production of cut filler, like tobacco stems or tobacco dust. It is used in the manufacture of tobacco products, including traditional cigarettes and heat-not-burn products. The use of homogenized tobacco material in the manufacture of tobacco products has helped to reduce waste and increase profits for tobacco companies. The production of homogenized tobacco material involves several steps, including pulping and refining cellulose fibers to form a pulp, grinding a blend of tobacco of one or more tobacco types, and mixing the pulp with a binder and water to form a slurry. The slurry is then processed to form homogenized tobacco material with a tensile strength adapted to withstand the forces acting on the material .

Technical parameters to specify in homogenized tobacco reviews

Technical parameters that can be specified in homogenized tobacco reviews include the tobacco types and grades used in the production of the material, the method of production, the target values for specific tobacco characteristics such as reducing sugars, and the resulting quality of the material. The production of homogenized tobacco material involves several steps, including pulping and refining cellulose fibers to form a pulp, grinding a blend of tobacco of one or more tobacco types, and mixing the pulp with a binder and water to form a slurry. The slurry is then processed to form homogenized tobacco material with a tensile strength adapted to withstand the forces acting on the material. Homogenized tobacco material is typically manufactured from parts of the tobacco plant that are less suited for the production of cut filler, like tobacco stems or tobacco dust. It is used in the manufacture of tobacco products, including traditional cigarettes and heat-not-burn products. The use of homogenized tobacco material in the manufacture of tobacco products has helped to reduce waste and increase profits for tobacco companies .

What are the technical parameters used to evaluate the quality of homogenized tobacco leaf

The technical parameters used to evaluate the quality of homogenized tobacco leaf include the tobacco types and grades used in the production of the material, the method of production, the target values for specific tobacco characteristics such as reducing sugars, and the resulting quality of the material. The quality of homogenized tobacco leaf can also be evaluated based on its essential characteristics, such as its taste, smell, and texture. The homogenization process helps to standardize the product’s quality and reduce costs. Homogenized tobacco leaf is typically manufactured from parts of the tobacco plant that are less suited for the production of cut filler, like tobacco stems or tobacco dust. The quality of homogenized tobacco leaf can be evaluated using a trainable grading system based on image processing techniques for automatic inspection and grading of flue-cured tobacco leaves .

The Benefits of Homogenized Tobacco

Homogenized tobacco has several benefits, including reducing the cost of production and improving the taste and aroma of cigarettes. The process of blending different types of tobacco leaves ensures that the final product is consistent in flavor and aroma, which is important for maintaining customer satisfaction.

The Drawbacks of Homogenized Tobacco

While homogenized tobacco has several benefits, there are also some drawbacks to its use. One of the main concerns is the potential health risks associated with smoking. Homogenized tobacco is often found in cheaper cigars that are made by machine, which are generally considered to be less healthy than premium, handmade cigars.

Homogenized tobacco vs reconstituted tobacco

Homogenized tobacco leaf ( HTL ) and reconstituted tobacco leaf ( RTL ) are both used in the manufacture of tobacco products. HTL is a mixture of chopped scrap tobacco and a cellulose adhesive that can be used as a wrapper or binder, while RTL is a reconstituted tobacco leaf mixed with stems and cellulose to create a usable tobacco-like leaf. HTL offers several benefits over traditional tobacco leaves, including standardized quality and reduced cost. RTL was developed by SWM and is also known as homogenized tobacco. The method of forming sheets of homogenized tobacco material usually involves a stage in which tobacco dust and binder are mixed to form pulp. Then this pulp is processed to form homogenized tobacco material. In the manufacture of tobacco products, besides tobacco leaves, homogenized tobacco material is used. This material is typically manufactured from parts of the tobacco plant that are less suited for the production of cut filler, like tobacco stems or tobacco dust. Homogenized tobacco material is usually the only source of tobacco or the main source of tobacco in heated aerosol-generating products .

The Future of Homogenized Tobacco

The future of homogenized tobacco is uncertain, with some experts predicting that it will continue to be used in the production of cheaper cigars that are made by machine, while others believe that it will eventually be phased out in favor of more natural and healthier alternatives.

Conclusion

Homogenized tobacco is a process that involves blending different types of tobacco leaves to produce a consistent product. While it has several benefits, including reducing the cost of production and improving the taste and aroma of cigarettes, there are also some drawbacks to its use, including potential health risks associated with smoking. As the tobacco industry continues to evolve, it will be interesting to see how homogenized tobacco fits into the future of tobacco production.

Books:

The books that cover the topic of homogenized tobacco include “Tobacco: A Cultural History of How an Exotic Plant Seduced Civilization” by Iain Gately and “Tobacco: The Story of How Tobacco Seduced the World” by Julian P. Gyngell .

Citations:

MyScienceWork. ( n.d. ). Homogenized Tobacco Material and Method of Production of Homogenized Tobacco Material. Retrieved from [https://www.mysciencework.com/patent/ru2694929c2] Google Patents. (2016). Homogenised tobacco material and method for production of homogenised tobacco material. Retrieved from [https://patents.google.com/patent/RU2694929C2/en] Google Patents. (2016). Homogenized tobacco material and method of production of homogenized tobacco material. Retrieved from [https://patents.google.com/patent/WO2016156598A1/en] Google Patents. (2015). Method for the production of homogenized tobacco material. Retrieved from [https://patents.google.com/patent/US10321707B2/en] Cigar Aficionado. (2016). Homogenized Tobacco Leaf. Retrieved from [https://www.cigaraficionado.com/glossary/homogenized-tobacco-leaf] Pulp and Paper Technology. (n.d.). Homogenized Tobacco Leaf | HTL Paper | Pura Paper Making Process. Retrieved from [https://www.pulpandpaper-technology.com/products/pura-paper-making-process/homogenized-tobacco-leaf-htl-paper]